Key Benefits

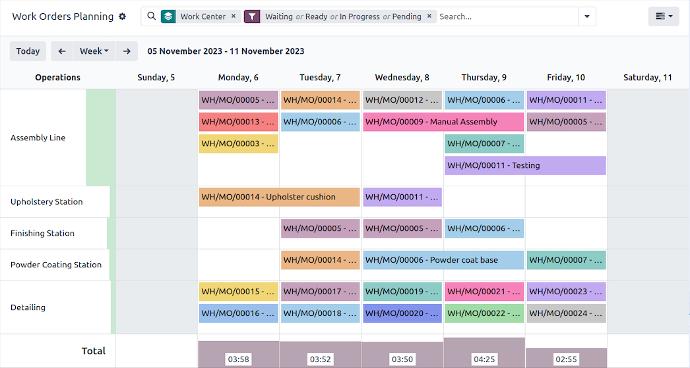

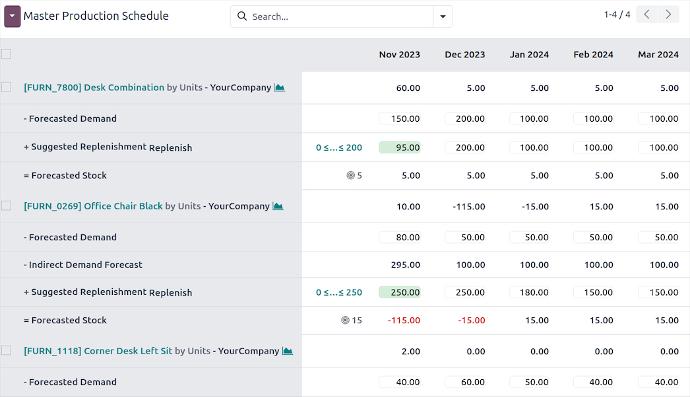

Production Planning and Scheduling

Our Manufacturing ERP system ensures seamless production planning and scheduling by integrating all aspects of the production process. With real-time data and automated workflows, you can efficiently manage work orders, allocate resources, and minimize downtime.

Key Features:

Automated production scheduling

Real-time work order management

Resource allocation optimization

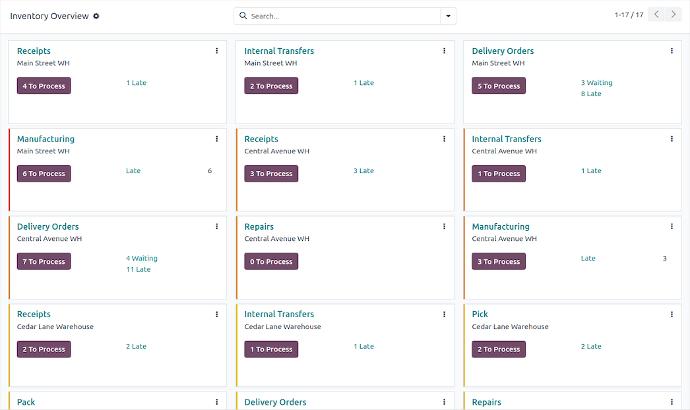

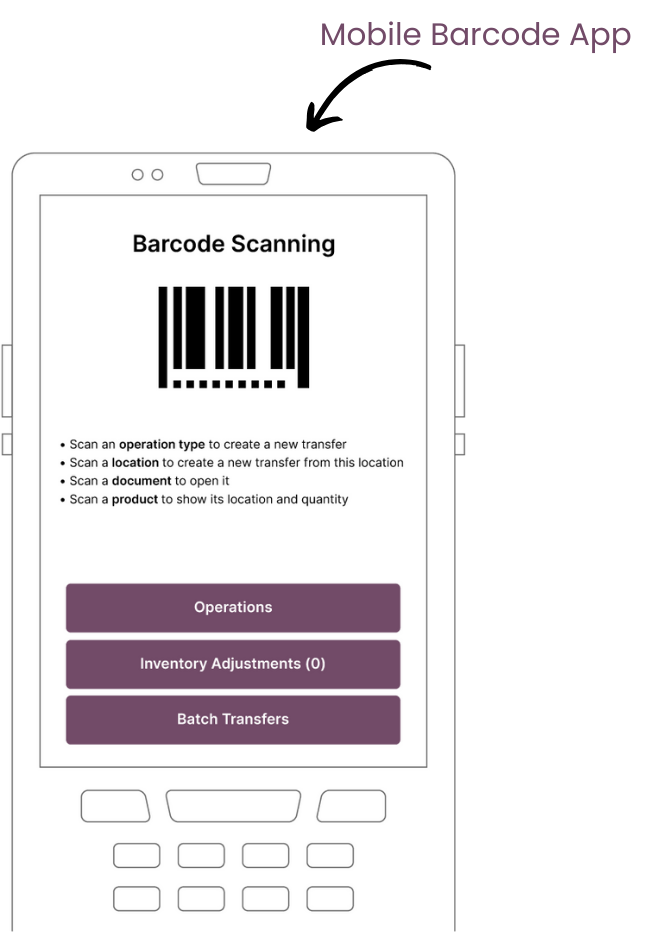

Inventory Management

Maintain optimal inventory levels and reduce carrying costs with our advanced inventory management features. Our ERP system provides real-time visibility into inventory, tracks raw materials and finished goods, and helps prevent stockouts and overstock situations.

Minimize picking movements

Choose the right strategy for you: single, cluster, wave, or batch picking. Trigger goods to release using multiple reservation strategies. Implementing the rights strategies allows to pick and pack 30% extra products with the same team.

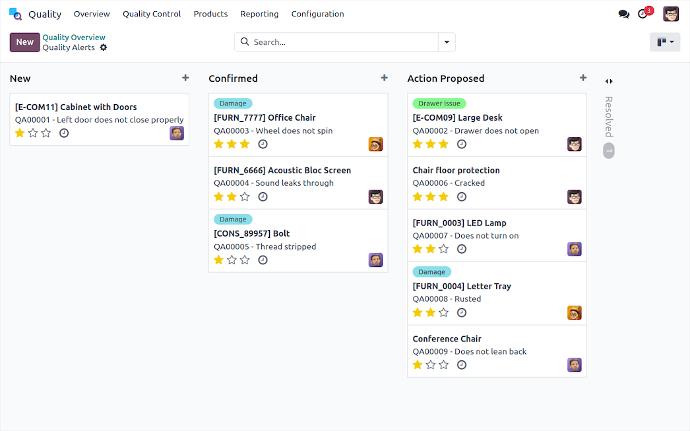

Quality Control

Ensure your products meet the highest quality standards with our comprehensive quality control features. Track and manage quality throughout the production process, from raw materials inspection to final product testing, ensuring compliance with industry standards.

Key Features:

Supply Chain Management

Optimize your supply chain operations with complete visibility and control. Our ERP solution enhances supplier collaboration, improves procurement processes, and ensures timely delivery of materials and products, reducing lead times and increasing efficiency.

Key Features:

Supplier management and collaboration tools

Procurement automation

Demand forecasting and planning

Features

Quality Control

Our ERP software's Quality Control module ensures your products consistently meet the highest standards. With customizable quality checks and detailed inspection protocols, you can identify and address defects promptly, maintaining product excellence and customer satisfaction.

Inventory Management

Optimize your stock levels with our ERP's Inventory Management feature. Track and control your inventory in real-time, manage stock movements seamlessly, and ensure you always have the necessary raw materials on hand for production. Say goodbye to shortages and overstock situations.

Accounting

Streamline your financial operations with our comprehensive Accounting Features. Manage accounts payable and receivable, generate accurate financial reports, and maintain compliance with ease. Our integrated financial tools ensure precise tracking and reporting, supporting better financial decision-making.

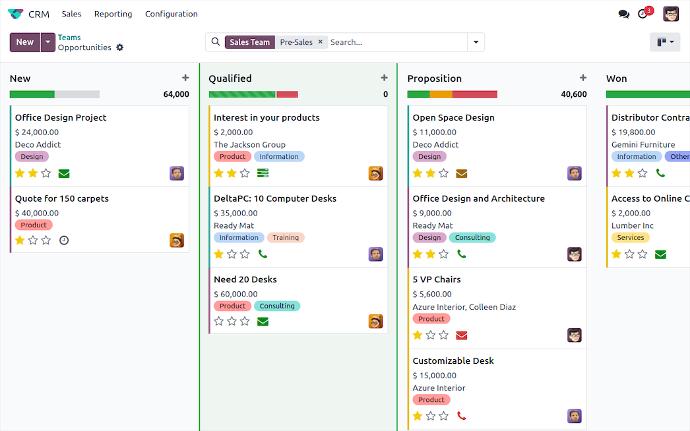

Customer Relationship Management (CRM)

Manufacturing ERP systems often include CRM modules to manage customer interactions, sales, and support. This feature tracks customer orders, preferences, and feedback, providing insights for product and service improvements. Enhancing customer relationships boosts satisfaction, loyalty, and sales growth.

Maintenance Management

Maintenance management modules in ERP software ensure regular upkeep of equipment, scheduling preventive maintenance, tracking repairs, and managing spare parts. This minimizes downtime, extends asset life, and cuts maintenance costs, enabling continuous production.

Product Lifecycle Management (PLM)

Manufacturing ERP software integrates PLM to manage the entire product lifecycle, from concept to retirement. It fosters collaboration across departments, ensuring stakeholders access the latest data. By integrating PLM, manufacturers boost development speed, innovation, and maintain consistency and quality throughout the product's lifecycle.

Salient Features

Services We Offer

Consulting

Meet and understand your unique business needs and goals.

Customization

Tailor the software to match the specific workflows and requirements of the enterprise.

Implementation

Execute a seamless deployment plan, ensuring minimal disruption and maximum efficiency.

Integration

Seamlessly integrate your ERP with existing systems for optimal data flow.

Support

Provide customized, proactive support to ensure smooth ERP operation.

Transform

Manufacturing Operations

with Confidence and Trust

Join us and make your company a better place.